Services

Solutions

STRATEGY DEVELOPMENT

AND DEPLOYMENT

Our Framework

Operational Excellence

Based on co-creating sustainable strategies that optimize your organization's critical processes.

We collaborate directly with leaders to implement measurable improvements in Safety, Quality, Delivery Times and Cost.

We foster a culture of continuous improvement. This process is supported by the creation of multidisciplinary teams that foster both technical and social skills, promoting a collaborative and proactive work environment.

Increased Efficiency

Lean methodologies streamline processes by eliminating waste , enabling your organization to operate more effectively and deliver products or services faster.

Cost Reduction

Buy optimizing resources allocation and reducing operational cost, lean strategies help improve your bottom line, resulting in increased profitability.

OPERATIONAL EXCELLENCE STRATEGY

We identify and enhance opportunities that generate long-term value, aligning strategic initiatives with your company's vision. Our methodology is based on a collaborative approach, ensuring that every action taken contributes to sustainable growth, improving competitiveness, engagement and customer satisfaction.

Informed Decision-Making:

Conducting a technical diagnosis allows executive managers to understand the current capabilities of their processes. This detailed analysis enables more informed decision-making regarding investments, technology upgrades, or process modifications

Benchmarking and Best Practices:

Through diagnosis, organizations can establish benchmarks for process performance and identify gaps compared to industry standards. This insight allows executive managers to implement best practices that lead to improved operational excellence

TECHNICAL DIAGNOSIS OF PROCESS CAPABILITIES

We carry out an exhaustive process redesign that aligns operations with your strategic objectives. We use customer-oriented tools to identify deviations and formulate action plans from the ground up. This not only optimizes efficiency, but also promotes an organizational culture focused on continuous improvement.

Enhanced Efficiency:

Business process redesign focuses on reimagining workflows to eliminate inefficiencies and bottlenecks. For executive managers, this translates into improved operational effectiveness, cost savings, and streamlined processes that contribute to the organization's strategic objectives.

Alignment with Customer Needs:

Through redesign, processes are better aligned with customer expectations and needs, enabling a more responsive and agile organization. This customer-centric approach helps executive managers maintain competitive advantage and strengthen customer loyalty.

BUSINESS

PROCESS REDESIGN

We invest in the development of your workforce, focusing on education and engagement as key drivers of sustainable growth. Through training and practicing improvement routines, we transform behaviors and cultivate an environment where everyone is empowered to lead change

Practical Implementation:

On-site strategies provide hands-on support to implement practices that drive sustained profitability. Executive managers benefit from having a structured approach to identifying opportunities for immediate improvements and long-term gains.

Cultural Change:

These strategies foster a culture of accountability and continuous improvement among employees, which can lead to increased engagement and committed teams. Executive managers can leverage this cultural shift to achieve lasting changes that support profitability objectives.

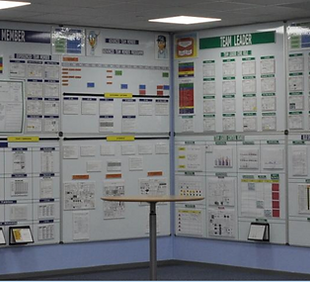

ON-SITE STRATEGIES

FOR SUSTAINED PROFITABILITY

Organizational Development

Hoshin Kanri Strategic Alignment Presential Workshop

Clear Direction:

A Hoshin Kanri workshop provides a structured approach to defining and aligning strategic objectives, ensuring everyone in the organization understands the direction.

Enhanced Collaboration:

By involving various department leaders, the workshop fosters inter-departmental collaboration, breaking down silos and promoting unity in achieving common goals.

Increased Accountability:

Defined roles and responsibilities lead to increased accountability among leaders and teams, motivating them to take ownership of their contributions.

Improved Performance Measurement:

The focus on measurable objectives enables the organization to track progress effectively, making data-driven adjustments to strategies as needed.Cultural Shift:The participative nature of the workshop promotes a culture of continuous improvement and strategic thinking, embedding Lean principles into the organizational mindset.

VALUE GENERATION

VSM

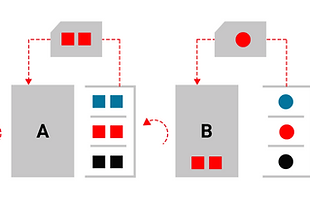

Value Stream Mapping (VSM)

VSM is a powerful Lean tool that helps organizations visualize and analyze their processes, making it especially valuable for high-level executives. Here’s how VSM can aid executives in driving improvements within their organizations:

- Enhanced Visibility of Processes

- Identification of Improvement Opportunities

- Alignment with Strategic Goals

- Fostering Cross-Functional Collaboration

-Supporting Data-Driven Decision Making

-Tracking Progress and Continuous Improvement

- mproved Customer Focus

In summary, Value Stream Mapping is a crucial tool for executives aiming to improve their organization’s efficiency and effectiveness. By utilizing VSM, executives gain clarity on processes, identify opportunities for enhancement, foster collaboration, and drive a continuous improvement culture—all of which are essential for sustaining competitive advantage in today’s dynamic business environment.

CONTINUOS

FLOW &

PULL SYSTEMS

IMPLEMENTATION

Reduced Lead Times

Continuos Flow and pull systems streamlines processes , minimizing delays and enabling faster response to costumer demand , which enhances overall efficiency and costumer satisfaction

Inventory Optimization

Theses Systems help maintain optimal inventory levels by producing only what is needed when it is needed . Reducing excess stock and lowering carrying cost while ensuring product availability.

Optimized Operations:

Implementing continuous flow and pull systems allows organizations to reduce lead times and inventory costs while improving responsiveness to customer demand. Executive managers can achieve smoother operations and enhanced efficiency across their supply chain and production processes.

Reduced Waste:

These systems help identify and eliminate waste in processes, enabling organizations to focus on value-added activities. Executive managers gain clarity on areas for improvement, allowing for targeted interventions that enhance overall productivity.

FACILITATION

OF KAIZEN

EVENTS

The Facilitation KAIZEN "improvements " Events service is a valuable resource for executive managers looking to implement effective change within their organizations. By leveraging expert facilitation, executives can foster collaboration, accelerate problem-solving, align initiatives with strategic goals, and build a sustainable culture of improvement—all essential for driving business success in a competitive landscape.

Structured Approach to Continuous Improvement

By providing clear frameworks and methodologies. This structure helps executive managers define specific goals and objectives for each event, ensuring that the improvement efforts are both focused and actionable

Expertise in Lean Methodologies

Consultants with expertise in Lean principles guide executive managers through the process of identifying inefficiencies and developing solutions. This expertise means that executives can leverage best practices and industry know-how, minimizing the learning curve associated with implementing Lean initiatives.

Objective Perspective

An external facilitator brings an impartial vie

wpoint to improvement events. , allowing for more objective discussions and evaluations. As a result, executive managers can make informed decisions based on factual insights.Accelerated Problem-SolvingWith a structured facilitation process, executive managers can expect quicker identification of issues and generation of creative solutions. The facilitator employs various tools and techniques to drive problem-solving discussions, allowing teams to focus on root causes and develop effective countermeasures in a timely manner.

Logistics Solutions

Conduct thorough process mapping to identify inefficiencies and waste in logistics operations. Our team will analyze current workflows and suggest lean improvements tailored to each organization’s specific context. Benefits

Enhanced Efficiency:

Streamlined processes lead to reduced cycle times and smoother operations.

Waste Reduction:

Identifying and eliminating waste improves resource utilization, saving costs.

Informed Decision-Making:

Detailed insights empower management with data-driven strategies for continuous improvement.

PROCESS MAPPING AND ASSESTMENT

Evaluate existing supply chain practices and implement best practices for optimization, focusing on inventory management, supplier relationships, and transportation efficiency. Benefits:

Cost Savings: Improved

Supply chain coordination can significantly lower logistics costs and increase profitability.

Improved Responsiveness:

A streamlined supply chain allows organizations to respond quickly to market changes and customer demands.

Risk Mitigation:

Enhanced visibility and control reduce vulnerabilities and potential disruptions in the supply chain.

SUPPLY CHAIN

OPTIMIZATION

Help organizations design and implement Just-in-Time inventory systems to align production schedules closely with customer demand, minimizing excess stock. Benefits:

Reduced Inventory Costs:

JIT minimizes inventory holding costs and reduces waste from unsold goods.

Increased Flexibility:

Organizations can adapt quicker to changes in consumer preferences, improving market competitiveness.

Enhanced Cash Flow:

Lower inventory levels free up capital for other operational needs, improving cash flow management.

Just-in-Time (JIT) Implementation

Provide comprehensive training programs focused on Lean principles, tools, and methodologies, empowering employees at all levels to identify and implement continuous improvement strategies. Benefits:

Skill Development:

Employees become proficient in Lean practices, fostering a culture of continuous improvement.

Empowered Workforce:

Engaged employees are more likely to contribute innovative solutions and take ownership of performance outcomes.

Sustained Growth:

A knowledgeable workforce strengthens long-term organizational resilience, maintaining competitive advantages in a dynamic market.

ORGANIZATIONAL CAPACITIES DEVELOPMENT

Lean Management System

Integrated Lean Performance Metrics

We assist organizations in establishing key

performance indicators (KPIs) that are closely aligned with Lean principles. This service ensures that metrics reflect both operational efficiency and customer value, leading to more effective performance management. Benefits:

Data-Driven Decision Making:

Establishing robust performance metrics enables data-based insights, allowing CEOs and operational teams to make informed decisions that drive organizational growth.

Clear Accountability:

Defining specific KPIs creates a framework for accountability among teams, aligning performance goals with Lean objectives.

Continuous Monitoring and Improvement:

Ongoing assessment of metrics allows organizations to track progress and identify new opportunities for Lean enhancements, supporting long-term success

Lean Assessment and Gap Analysis

A comprehensive evaluation of current processes versus Lean best practices, identifying gaps and areas for improvement within the organization.

Benefits:

Targeted Improvement Areas:

Focus resources on specific processes that will yield the greatest improvement.

Benchmarking:

Gain a relative understanding of performance against industry standards or competitors.

Strategic Roadmap Development:

Creates a clear pathway to Lean transformation, minimizing wasted effort.

Customer Feedback and Value Proposition Analysis

Assessing customer feedback and aligning the company's value propositions with Lean principles to maximize customer value.

Benefits:

Enhanced Customer Insights:

Deepening understanding of customer needs leads to better product and service alignment.

Stronger Market Position:

Companies can differentiate themselves by delivering exceptional value that meets customer demands.

Sustained Competitive Advantage:

Continuous feedback loops contribute to ongoing adaptation and improvement, essential in today’s market dynamics

Just-In-Time (JIT) Inventory Management

Implementing JIT principles to minimize inventory levels while ensuring that materials are available when needed to meet customer demand.

Reduced Holding Costs:

Lower inventory levels decrease storage costs, freeing up capital for other investments.

Increased Cash Flow:

Less money tied up in inventory improves overall liquidity.

Enhanced Responsiveness:

Streamlined inventory management allows organizations to respond more swiftly to market changes.